contact us

contact us

Fo Shan Xin Chuang Decorative Material Co,. Ltd.

We provide customers with various kinds of quality interior decoration panels including laminated board sheets and high gloss mdf panels with high-quality services.

If you would like to leave us a comment please go to contact us

LCT Gloss Laminated MDF

For LCT laminated MDF Board, it is one of the most successful serials from ZHIHUA Company in recent years. The surface material is 0.5mm PETG imported from Korea, after laminated onto 18mm MDF Board, the LCT Board looks super flat in the surface. And Korea manufacturer guarantees that no any color difference or change to the gloss surface. The LCT laminated mdf board has been highly accepted by the Western countries like USA, Australia, France, Canada etc., even though it is sold at higher price than other gloss MDF board. There are super gloss and super matt models are follows:

The advantage of ZHIHUA LCT laminated MDF Board is as followings:

1) Super flat in the surface where you can not find any waves or bubbles.

2) No color difference between different batches.

3) No color changes and long life span.

4) Scratch resistance and high gloss / matt in the surface.

5) The LCT film can be laminated onto MDF, Plywood or Particle Board as per customers’ requirements.

Global consumption of wood artificial panels is growing and new investments are being made to meet these needs. However, with the increasing demand for laminated MDF board and the competition from biomass energy industry, people pay more and more attention to the future availability of wood. Now let’s get to the production process of it. The production process of laminated MDF board is relatively complex, but it can generally include the following main processes.

First of all, cutting technology should be used in raw material treatment and final processing, such as veneer spinning, planing wood chips, planing cutting, fiber grinding and separation, as well as sawing and sanding in final processing. Cutting wood into units of different shapes and recombining them into various plates in a certain way can improve some properties of laminated MDF board, such as anisotropy, heterogeneity, wet expansion and dry shrinkage. The mechanical strength of the plate composed of large units is much higher, and the homogeneity of the plates composed of small units is much better.

Second of all, drying includes veneer drying, planer drying, dry fiberboard drying and wet fiberboard heat treatment. The drying process and process control are different from those of wood drying. The process control of wood drying is based on the relative humidity of drying medium, so attention must be paid to prevent the generation of drying stress. However, the drying of flake and granular materials used in laminated MDF board is carried out at relatively high temperature, high speed and continuous conditions, and immediately changes to the deceleration drying stage at the end of the heating stage. Veneer and planer and other materials are thin, with large surface area, and drying stress is little or no effect. In addition, in the cutting process, the wood tissue relaxes in varying degrees, the resistance of water diffusion is small, and the law of water diffusion in wood is meaningless to veneer, shavings and so on. Most of the dry heat sources are steam or combustion gas.

Third of all, the billet of molding and compression plywood and the slab forming and compression of particle board fiberboard belong to the molding process of wood-based panel. Pressure preloading and hot pressing are the main two ways of pressing. The slab must be preloaded when using the gasket-free system. It keeps the slab from damage when pushing the hot press. Hot pressing process is the key process to determine the production capacity and output of enterprises. The hot pressing equipment commonly used in wood-based panel industry is mainly multi-layer hot press. In addition, single-layer large format hot press and continuous hot press are also gradually adopted. Single-layer hot press is often used in particle board factory, and single-layer press can be used in the manufacture of laminated MDF board to realize the combined heating of high frequency and steam, which is beneficial to shorten the pressure cycle and improve the uniformity of product section density.

The last but not the least, after the final processing plate is discharged from the hot press, the cutting edge, the sand light and the hard fiber board are subjected to heat treatment and humidity control treatment through the cooling and water content balance stage. In accordance with the requirements of use, some laminated MDF boards shall also be subjected to special treatment such as dipping, painting, compounding, sealing, etc.

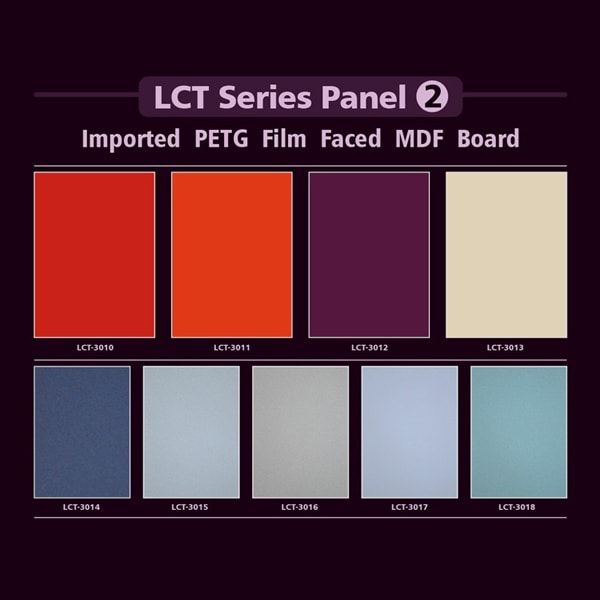

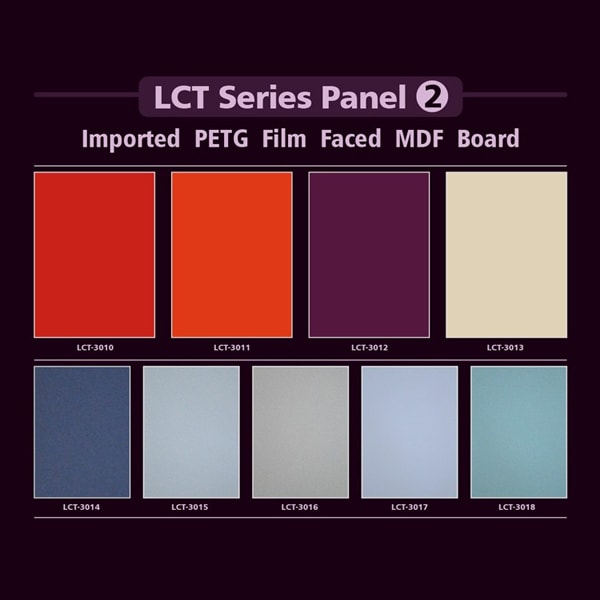

COLOR

PRODUCT SPECIFICATIONS

|

Material |

high gloss PETG sheets laminated on MDF board |

|

Designs |

36 different color |

|

Size |

Standard size 2440*1220 |

|

Thickness |

10mm,13mm,17mm,19mm |

|

Colors |

Solid color |

|

Board grade |

E1, E2,CARB P2 |

|

Features |

high brightness, rich color, extremely smooth surface high-hardness, scratch resistant anti-oxidant, anti-yellowing, no color fading or UV peeling off , waterproof, anti-bacterium, acid and alkali resistant easy to clean and process No color difference between different batches; |

|

Applications |

kitchen cabinet /wardrobe / interior decoration for bedroo m, living room, bathroom / TV stand/ exhibition panel/bookshelf/ shoe cabinet |

|

MOQ |

200 sheets |

|

Package |

We offer both pallet loose packing and pallet packing:For loose packing,1X20' container can load 460 sheets,for pallet packing,1X20' Container can load 400 sheets in 8 pallets,each pallet in 50 sheets. |

|

Lead time |

7-15 days after deposit received |

OUR WAREHOUSE

Related Products